Seeds processing, conditioning and packing are vital operations for enhancing the seed quality and physical appearance. Seed treatment with fungicide, nutrients and chemicals protect the seed from insect pest damage seed-borne/ soil borne fungal diseases for a specific period. While processing seeds the critical parameters that need to be kept in mind include aspects such as germination percentage, seed viability and improved seed health. In Bapna Seeds processing centers, the seed is conditioned to retain its inherent quality parameters (Germination, G.P.) and improve physical parameters. Additionally physical impurities in seed batches such as undersized seeds and light seeds are removed and right amount of moisture is retained. The processing cycle involves different steps, which varies with the type of crop.

It is important to store seeds properly so that there is no less in their quality parameters. The conditioned warehouses ensure medium to long term storage of seeds without loss of viability and vigor. In the conditioned warehouse, temperature levels and relative humidity are maintained constantly by using air conditioning and de-humidification equipment. Our seeds storage capacity is 1.5 lakhs qtls including cold storage facility available.

We saw the finest seeds and reap bountiful harvests. Though quantity is the desired outcome for any industry or business enterprise, Bapna Seeds differ in this fundamentally. We believe that quantity with top quality service to their valuable customers would result in more enduring and gainful relationship that any momentary success. Therefore a regimental approach to a result oriented quality control system is implemented at all stages. Our unique quality control features include testing for germination, genetic purity and quality assurance. A dedicated and professional team is employed to monitor the quality of seeds at all times.

Field quality assumes a great significance in view of the fact that most of the hybrids belong to cross pollinated/often cross pollinated crop species and the contamination at field level is quite possible. The following precautions are taken to ensure quality at field level.

Proper field inspections and rouging by the experience and qualified production staff insures genetic purity, seed health and seed viability.

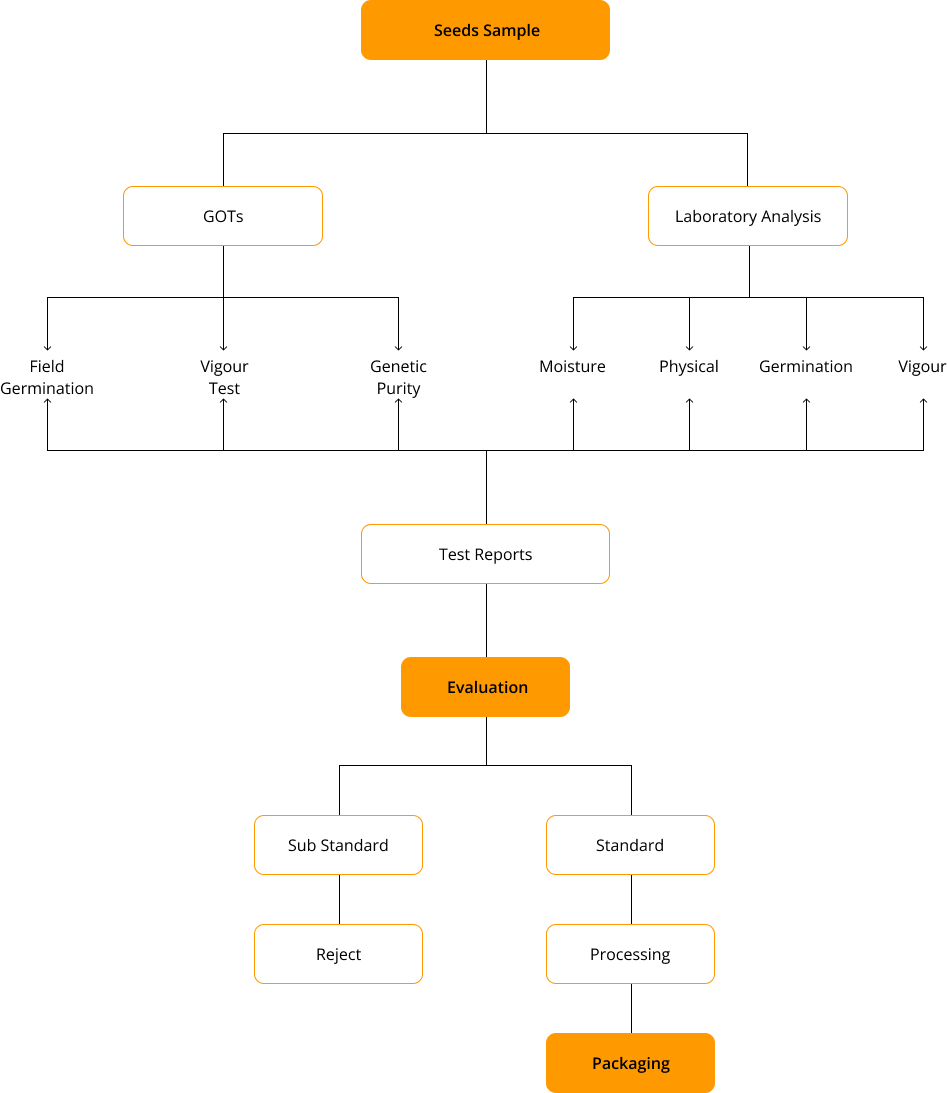

Bapna Seeds has built up all necessary facilities to ensure the best seed quality at laboratory level. The following - chart of activities depicts the different stages of quality assurance.